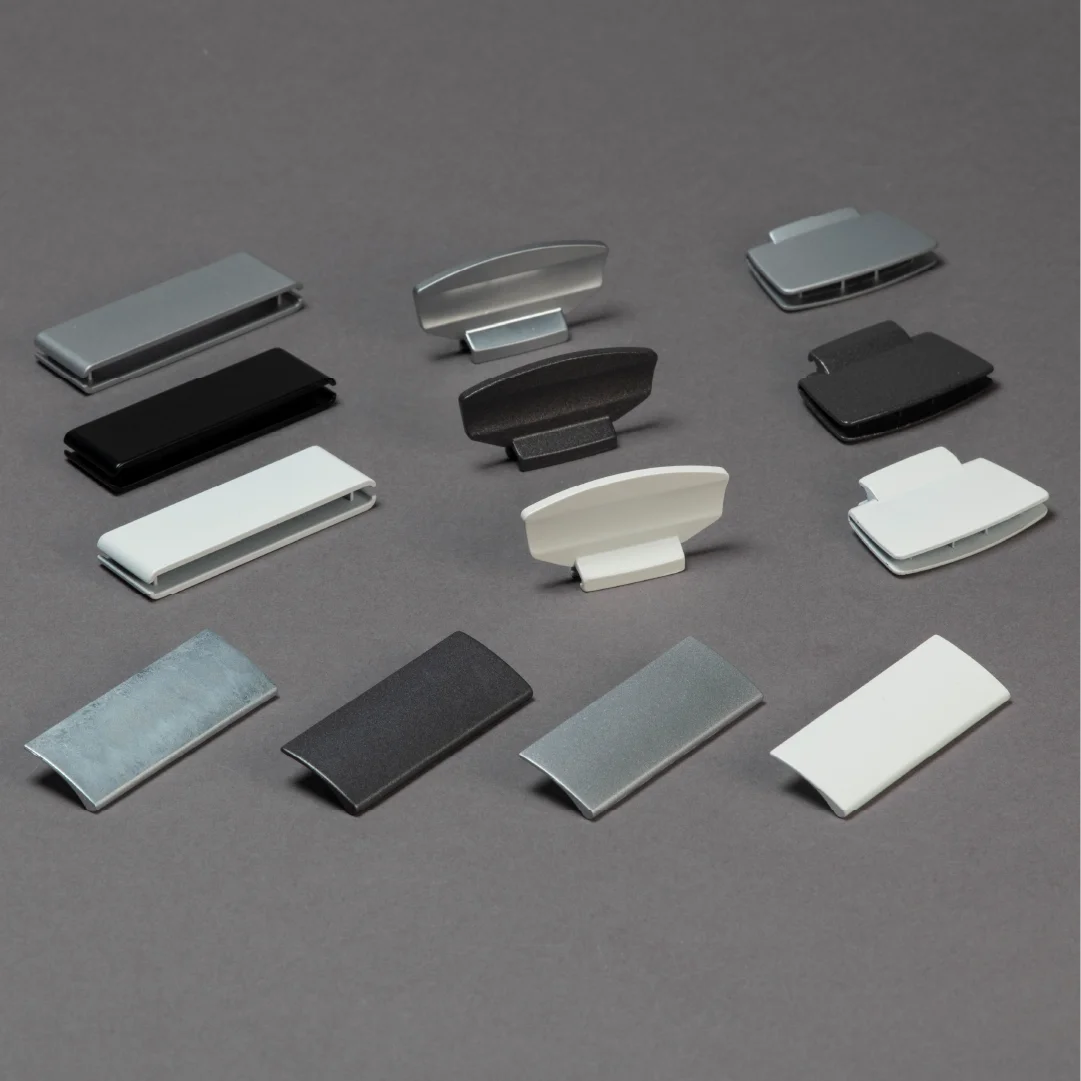

To achieve the best results from zamak die casting, it is essential to select surface finishes and treatments capable of enhancing component performance. These processes optimize the product according to its application and industry of use, improving resistance, durability, protection against external agents, and aesthetic quality.

Below we analyze the main surface finishes and treatments for zamak, detailing processes, advantages, applications, and technical characteristics—such as coating thickness and salt spray resistance—to support the selection of the most suitable solution for production needs.

Finishes and treatments:

Liquid painting

Liquid painting on zamak requires expertise, careful preparation, and the use of specific products to ensure a resistant, uniform, and long-lasting result.

The process is carried out by spray gun, applying the coating in one or more layers depending on the type of liquid paint used and the purpose of the coating (primer, finish, or intermediate layer).

Industrial liquid painting is suitable for all metallic materials and offers high resistance to impacts and chemical agents, as well as good corrosion protection.

Powder coating

Powder coating, also known as electrostatic coating, uses powder-based pigments made from synthetic resins that adhere perfectly to surfaces.

Powders can be divided into four main categories:

- Epoxy powders, offering excellent mechanical, chemical, and corrosion resistance, even with low-temperature curing, but poor UV resistance; often used as primers.

- Hybrid powders (epoxy-polyester), often a more cost-effective alternative to epoxy powders. Corrosion resistance is lower, but other performance characteristics are similar.

- Polyester powders, ideal for outdoor applications thanks to good UV resistance and reliable corrosion protection.

- Acrylic powders, offering excellent UV and chemical resistance and very good flow properties, but lower mechanical resistance compared to polyesters.

Curing at high temperatures melts the powder, forming a paint film. After cooling, the component features a compact, uniform coating with exceptional scratch resistance.

Cataphoretic coating

Cataphoresis is an immersion electro-deposition painting process using direct current.

The deposited film provides high anti-corrosion properties, ensuring long-lasting protection even on areas that are difficult to reach with traditional spray systems.

Electrolytic nickel plating (barrel plating)

Electrolytic nickel plating is a coating process that uses electric current to deposit a layer of nickel onto the base metal surface.

In this method, the component acts as the cathode, while a nickel anode dissolves into the electrolyte, releasing nickel ions.

Key features include:

- Precise thickness control: electric current allows accurate regulation of the nickel layer thickness.

- High adhesion: the coating adheres perfectly to the substrate, ensuring strength and durability.

Electrolytic zinc plating

Electrolytic zinc plating consists of the galvanic application of a zinc layer, with coating thickness typically ranging from 2 µm to 20 µm.

After zinc plating, the component is immersed in a passivation bath that creates a thin protective film. This additional layer further improves corrosion resistance, provides different aesthetic finishes, and offers specific functional properties.

Four main types of passivation are available on the market: blue-white, yellow iridescent, black, and green.

An additional post-passivation sealer can be applied to further increase corrosion resistance and coating lubricity.

Chromate passivation (chromating)

Chromate passivation is valued for its ability to provide excellent corrosion protection without altering dimensions, mechanical properties, or electrical conductivity of the base metal.

This process is widely used to ensure reliable protection for zamak components intended for aggressive environments.

Zinc Nickel

Zinc-nickel treatment is an electrolytic deposition process of a binary zinc-nickel alloy, obtained through alkaline galvanic baths that co-deposit zinc and nickel simultaneously using specific additives.

Cerakote

Cerakote is a thin-film ceramic-polymer composite coating with a proprietary formulation that ensures:

- low thickness

- high resistance to high temperatures and corrosion

- excellent UV stability

It is applied by spray gun as a thin layer and subsequently cured using heat or air.

Heavy-duty electroplating (chrome, nickel, gold plating)

Heavy-duty electroplating for chrome, gold, and nickel uses an electrolytic process to deposit protective and decorative metal layers onto zinc alloys (zamak).

This treatment significantly enhances corrosion resistance and aesthetic appearance and often includes an intermediate copper layer to improve adhesion of subsequent coatings.