Surface finishes

1. Die casting moulds and co-design

2. Mould construction and maintenance

3. Zamak die casting

4. Quality Control and Metrology

5. Machining

6. Surface finishes

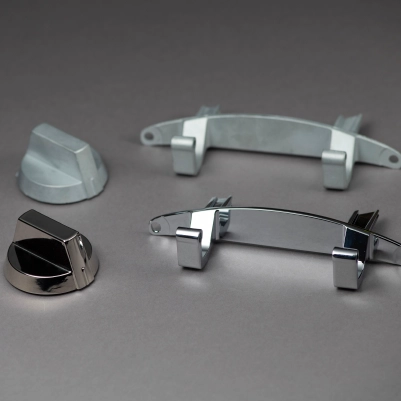

Galvanic coatings and surface finishes

The establishment of a consolidated network of specialized suppliers in the span of only 20 km allows us to guarantee the delivery in a short time of a complete finished product also with regard to aesthetic surface finishes, such as galvanic coatings (chrome plating, brass-plating, gold-plating, nickel-plating, zinc–plating, chromic passivation), grinding, cleaning, vibropolishing and non-metallic coating (KTL, powder coating or liquid coating).

All the finishing operations carried out by third parties are carried out under the supervision of our quality department, in order to ensure the customer a supply that perfectly meets their requests both in terms of treatment resistance, measured through hours resistance in salt mist, both in purely aesthetic terms.

Deburring, tumbling, and sandblasting

As a result of the moulding, we are equipped to internally perform deburring and tumbling operations through different sized tumblers with manual or automatic unloading. We can also turn to external suppliers, with whom we boast consolidated partnerships, for the realization of belt, frame, and tunnel sandblasting, and the thermal burr that exploits the trigger of a gas mixture that wraps the parts to be able to remove the burrs of the smallest size and in the most difficult to reach positions.