In the automotive sector, the precision and reliability of components play a key role in ensuring the proper functioning of vehicles and the continuity of production lines.

With this in mind, we have developed an advanced quality control solution for a client involved in the production of automotive armrests.

Zinc part for automotive: Custom automatic control system

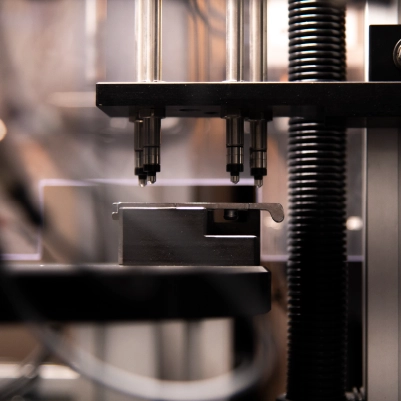

To meet the customer’s needs, we designed and implemented an automated workstation dedicated to inspecting critical dimensional features. This system allows for 100% inspection of all parts produced, ensuring total compliance and smooth integration into the customer’s automated armrest assembly line.

In particular, the 100% inspection includes checks on the zinc part such as:

- Presence of part deformation

- Flatness and perpendicularity checks

- Burr presence control, in the coupling area

The attention to detail in the inspection phase ensures that every component meets the quality standards required by the automotive industry, where precision is synonymous of reliability. Thanks to our IATF (ISO/TS 16949) certification, our zinc die casting company remains a trusted partner for TIER 1 suppliers and a recognized reference for OEMs.